Agricultural Ventilation Concepts For Livestock Keeping

A guide to choosing the right ventilation concept for your farm

In this guide, you’ll read about the different ventilation concepts used in poultry and pig housing around the world. A ventilation concept is how you position air inlets, chimneys, fans, etc. in the barn. When we look around we see that every house or farm is different and you will find that there are variations on these concepts. For the animals, when we talk about poultry we mean birds in the broader sense of the word. For example ducks, geese, turkeys, and other birds.

Each climate is different as is each farm

Not only is there a difference in animal species, but there is also a difference in the specialization of farmers. Some keep parent stock, others keep laying hens or fattening pigs. Each species and type of animal requires a different kind of housing and thus a different ventilation concept. In what way the farm is constructed also depends on the country where it is built. It can be made out of wood, concrete, or sandwich panel. And that is not all, different laws and legislation apply per country.

Optimizing indoor climates for animal health and better performance

When you want to create an optimal production and animal performance having the right climate conditions is key. When looking at climate it is established that the ventilation system is of utmost importance. Ventilation plays a central role as it used to keep air quality levels perfect for the animals in a variety of ways. For example, when it is too cold pigs will tend to eat more, when it is too hot they eat less. For all animals the optimal growth rate, feed conversion, and meat yield depend heavily on an optimized indoor climate and your ventilation concept becomes key in optimizing the indoor climate.

Characteristics of indoor climates

An indoor climate consists of heating, light, temperature, humidity, airspeed & quality. Except for lighting, the ventilation system plays a central role in modern-day. Now, we know that maintaining a good climate inside the house should be your primary goal. But it is heavily affected by the climate outdoors. Basically keeping a good climate depends on how much you can control and influence the outside climate to your preference. A direct bridge between the outside and inside climate is the ventilation system.

When we look at keeping indoor climates stable the value of insulation comes in to play. Good insulation values of the walls, roof, floors, and such are key, and since the ventilation makes a bridge between the outside and inside of the house. It is logical that the air inlet valves should also be insulated. This is the reason we produce our entire program out of high-quality Polyurethane.

It will come as no surprise that a good ventilation concept also brings benefits to other aspects such as saving on electricity, heating, and water consumption costs. Next to this, a healthy climate helps prevent an excessive need for antibiotics or vaccines.

Where TPI can help you choose the right ventilation concept

Here at TPI we provide solutions, services and advice for every type of livestock ventilation imaginable. Not only do we have knowledge of the pig and poultry sectors we also have experience with horses, goats, cattle and even insect farms. With dedicated sales managers we strive to give you the best advice and solutions all over the world.

Choosing the right concept for your farm.

When we see the different ventilation concepts we feel that the local outdoor climate always plays a role in the style of building and ventilation concept that is used. Your farm can be located in an area that has huge seasonal changes with an extreme difference in temperature. Or maybe it is located near the tropics where the temperature doesn’t change too much with the season but rain and humidity do.

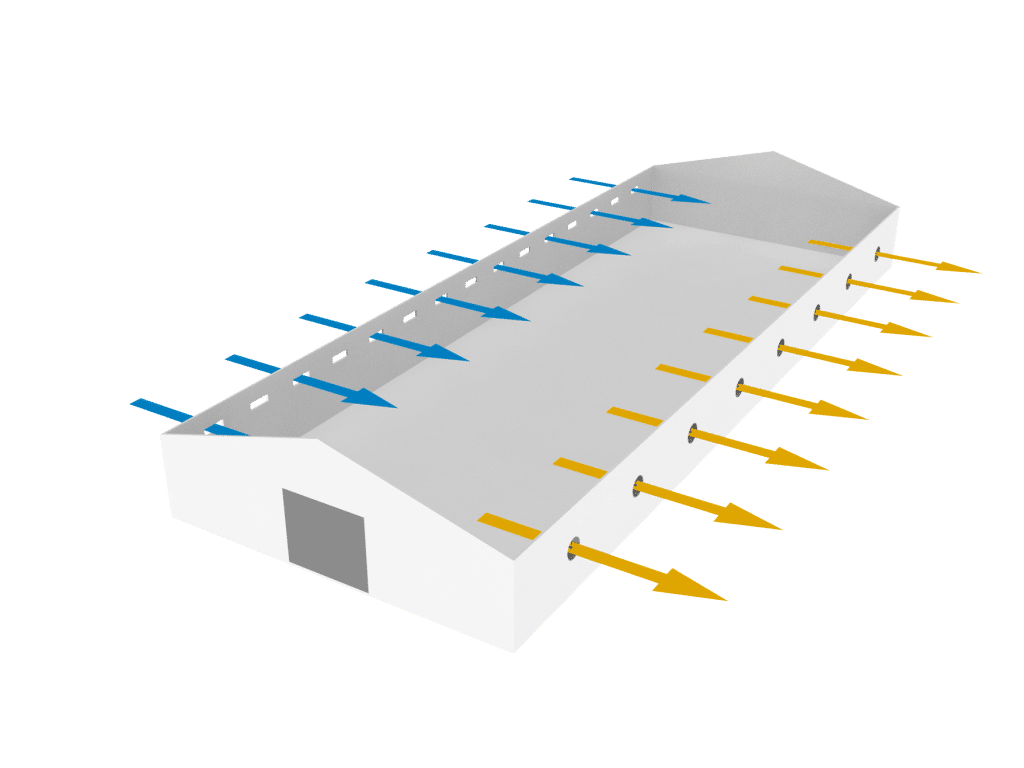

Cross Ventilation Concept

Cross ventilation is ideal for houses that have either doors, maintenance or processing rooms on the gable sides. In a cross ventilation set-up air inlet valves are installed in the sidewall. In the opposite sidewall fans take out the air after it has crossed the width of the building hence the name. This type of ventilation is especially suitable for narrow houses. For poultry houses that require some form of cooling but where tunnel ventilation is no option, cross ventilation is the ideal solution.

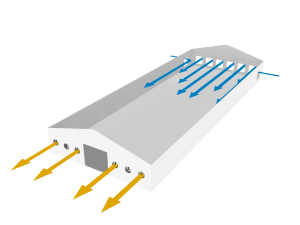

Longitudinal Ventilation Concept

Longitudinal ventilation is mostly used in wider houses. It is also suitable for houses with obstacles such as aviaries, pens, cages, walkways, boarding and such. The basic principle is that air is taken in through air inlet vents alongside both sidewalls of the building. The exhaust of dirty air in this concept is done with big fans in the end gable wall. These fans are built with a cascade control to gradually increase the capacity as animals grow bigger or as the temperature rises.

We see this type of ventilation all over the world as it is one of the most popular kinds of ventilation. This concept works for almost all types of animals.

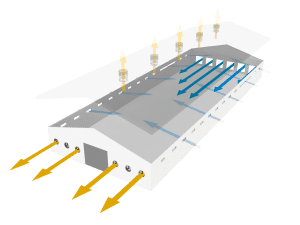

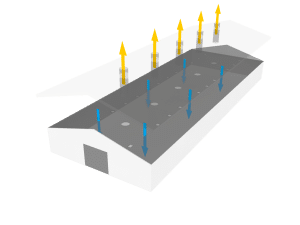

Roof Ventilation Concept

Roof ventilation makes use of air inlet valves in both side walls to take air into the house. Exhaust chimneys on the roof take out the dirty air. This method of ventilation is used for example when exhaust fans in the end gables are not an option. This is a very common concept we often see in use worldwide, in both poultry houses and pig farms.

This concept is easily usable in poultry houses located in intermediate climate zones. For pigs this concept also works well when air inlets with straight inner valves are used. Straight inner valves help guide the air upwards to the ceiling thus preventing cold air from dropping onto the animals to early. In combination with a heating system for winter and a spray cooling (or fogging) system for summer, this concept works well for most houses.

Tunnel Ventilation Concept

Tunnel ventilation is mostly used in combination with other ventilation concepts. This concept is perfect for cooling birds during hot summer days or when approaching max weight. A combination of this ventilation concept with cooling pads in particular is a great way to cool birds.

For pigs this type of ventilation is not desirable but sometimes needed. Pigs do not have fur or any type of protective coat therefore they are much more sensitive for draft. When it gets really hot we sometimes see farmers having no other option but to use some tunnel ventilation.

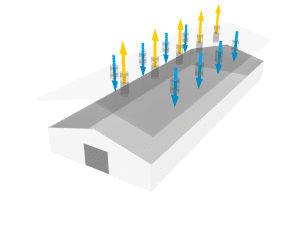

Combined Roof – Tunnel Ventilation Concept

This is a combination of two concepts. During minimum ventilation (or low temperatures) the air enters through air inlet valves in both sidewalls. Exhaust air is taken out of the house via exhaust chimneys. During maximum ventilation, the tunnel units are opened and the airspeed increases in order to cool the animals. Big exhaust fans in the end gable take the air out.

This concept is very useful for keeping birds as it offers a lot of control over a wide range of temperatures and climate conditions. During cold periods the chimneys make sure there is no draft over the length of the house. When there is an intermediate period both sidewall inlets and gable fans can offer some cooling before the tunneling starts. During hot periods the tunnel ventilation system takes care of cooling and chimneys are completely closed.

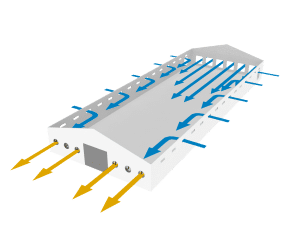

Combined Longitudinal – Tunnel Ventilation Concept

This is again a combination of two concepts only in this case there are no chimneys used. During the minimum ventilation phases, the air is taken in through sidewall vents. When it gets warmer or when the animals start to gain weight significantly, the tunnel ventilation starts and is gradually increased. The exhaust air is taken out of the house by fans in the end gable.

This concept is again a concept mostly seen in poultry and not so much in pig housing. For poultry, this ventilation concept is widely used in warmer climates around the world. Longitudinal ventilation already brings some airflow or draft over the length of the house and when tunnels are gradually opened they add to that effect. In combination with cooling pads, this system works well in hot weather circumstances.

Ceiling Ventilation Concept

Ceiling ventilation uses air intake valves mounted in the ceiling between the attic and the populated part of the house. In this attic the air is pre-heated so cold air cannot drop directly onto the animals. The exhaust air is taken out of the house via the floor or gable fans. This ventilation method is very reliable in the colder parts of the world. Basically incoming air is preconditioned before reaching the animals. In many cold areas, we see this system as preferable in pig farms. For poultry, equal benefits are observed in cold areas.

Chimney Ventilation

Chimney ventilation is the perfect solution when the side walls cannot be used to place air vents. In this concept, both the intake and exhaust of air are organized through chimneys. In most houses, this concept works with negative pressure meaning only the exhaust chimneys are equipped with fans. For free-range poultry houses or houses with equal pressure concepts, chimneys are the perfect solution. In the equal pressure set-up, both intake and exhaust chimneys are equipped with fans to actively push clean air in and pull dirty air out.

Chimneys give the opportunity to create a balanced spread of fresh air that reaches all corners of the house. Chimneys are therefore favorable in very wide houses with cages or aviaries. For pig housing, the intake chimneys should be recirculation chimneys as the help to pre-condition the incomming air. By mixing warm air from inside the house with fresh outside air you can ensure no cold air drop falls directly onto the animals.

Get in touch!

As part of our job, we would be happy to further inform you about the possibilities of the different ventilation concepts. As we have said before, many varieties are possible but for each farm, we can offer optimized solutions. Write us an email or call to +31 (0)73 – 6569194! We are always happy to help!